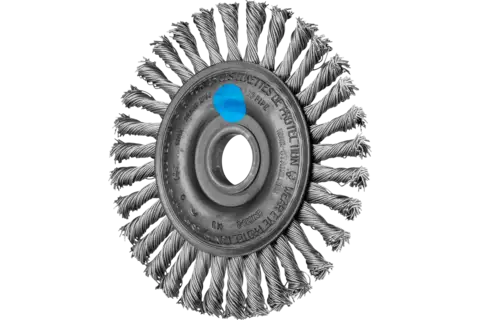

Wheel brushes, knotted, pipeline

PIPELINE brush knotted RBG dia. 100x6x22.2 mm stainless steel wire dia. 0.50 mm angle grinders

Technical information

PIPELINE brush knotted RBG dia. 100x6x22.2 mm stainless steel wire dia. 0.50 mm angle grinders

- Dia. external

- 100 mm

- Dia. filament material

- 0.5 mm

- Dia. hole

- 16 mm

- Dia. thread

- 0

- Filament material

- Stainless steel wire (INOX)

- Length, filament

- 19 mm

- Max. RPM

- 20000 RPM

- Mounting X-LOCK

- without

- Mounting system

- Centre hole

- Number, knots

- 32 pcs.

- RPM, optimum, from

- 8000 RPM

- RPM, optimum, to

- 15000 RPM

- Width

- 6 mm

- Packaging unit

- 10 pieces

Description

Advantages

Recommendations for use

- Materials that can be worked

- Applications

- Drive types