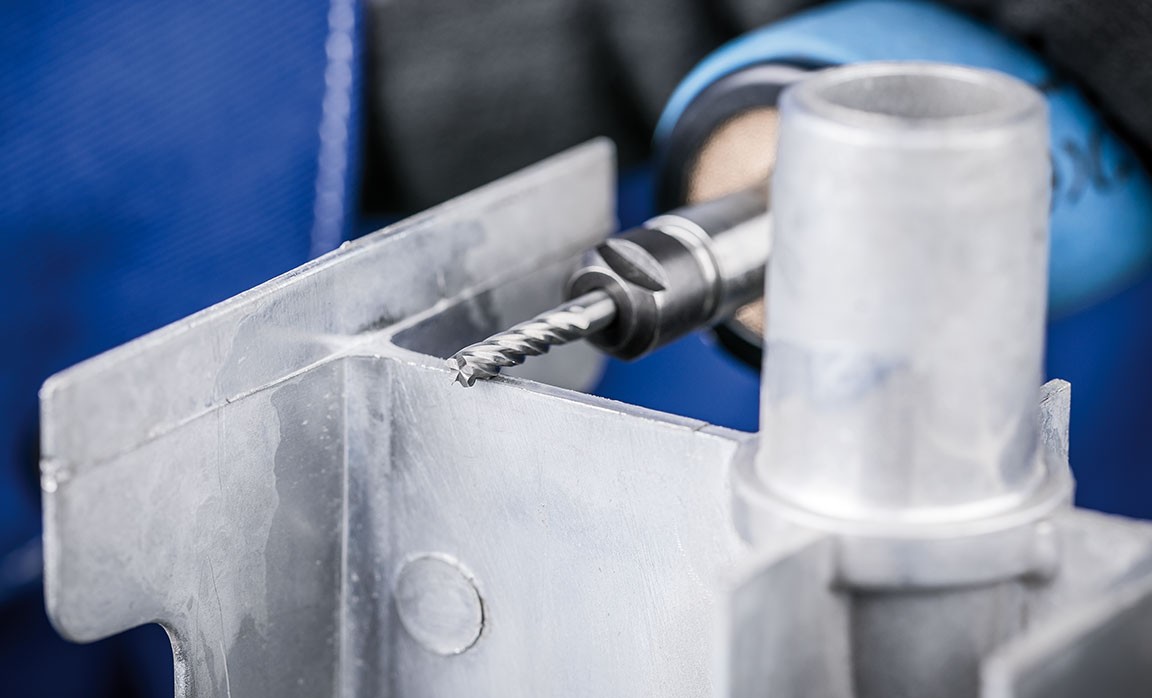

TC burrs - ALU cut

PFERD TOOLS has further developed the ALU cut especially for stock removal on aluminium. This cut is characterized by its high stock removal rate.

Advantages:

- Extremely high stock removal rate.

- Large chips.

- Reduced material adhesion.

- Long tool life and smooth running.

- Can be used with cutting speeds of up to 1,100 m/min.

- Reduced wear on the tool drive due to impact-free work without chatter marks, thanks to the high concentricity.

Materials that can be worked:

- Aluminium

- Bronze

- Copper

- Brass

- Titanium

- Titanium alloys

- Zinc

- Fibre-reinforced plastics (GRP/CRP)

- Thermoplastics

Applications:

- Milling out

- Levelling

- Deburring

- Cutting out holes

- Surface work

- Work on weld seams

Matching tool drives:

- Flexible shaft drive

- Straight grinder

- Robot

- Machine tools

Recommendations for use:

- If possible, use the tools on powerful drives with elastically mounted spindles to avoid vibration.

- For the cost-effective use of burrs, work with higher rotational/cutting speeds. Power recommendation for tool drives:

- Shank diameter of 3 mm: 75 to 300 watts

- Shank diameter of 6 mm: from 500 watts

- Please observe the rotational speed recommendations.