Recommendations for use when working on aluminium

Success when working on aluminium depends on many factors. We have briefly summarized the most important points for you in the following.

What influences working on aluminium?

For success when working on aluminium materials, we recommend always taking the stock removal behaviour of the various alloys into consideration. Based on the alloy and heat treatment state, the stock removal behaviour can be viscous and smearing or brittle and hard.

The hardness of the aluminium material to be processed is decisive. An optimal tool cutting geometry reduces the creation of built-up edges and the clogging of the tool. With an optimal geometry, the performance level and tool life increase dramatically. Find out how to prevent burrs from clogging here.

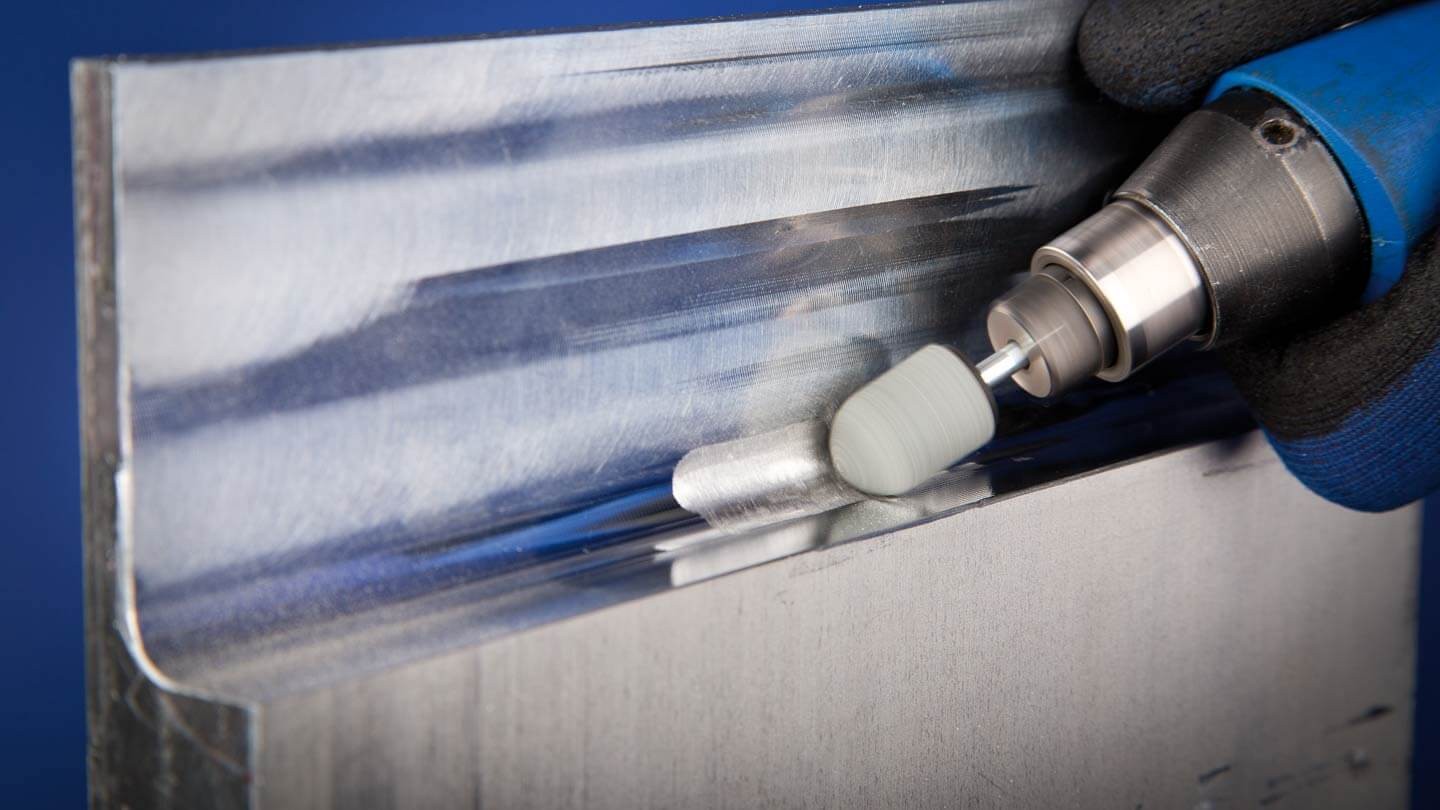

For mechanical work on aluminium surfaces, what factors must be taken into consideration?

The corrosion behaviour of aluminium materials is strongly influenced by the surface quality and its alteration through grinding, polishing and brushing.

Smoothing has a positive effect and roughening has a negative effect on corrosion resistance. Pressing foreign bodies into the surface also reduces corrosion resistance.

Mechanical work on the surfaces of pure aluminium and aluminium alloys with a Brinell hardness that is less than 40 HB requires care and experience.

The pressure applied during grinding and polishing must take the material’s specific hardness into consideration, as soft materials have a tendency to smear, fragments and abrasives can become pressed into the surface of the workpiece and the visual finishing effect can become non-existent.

Which recommendations must be taken into consideration when processing aluminium?

Cutting speed and rotational speed, contact pressure, cooling and corrosion protection: In the following sections, we have compiled our recommendations for processing aluminium for you.

What cutting speed is suitable for processing aluminium?

To optimise surface quality, the cutting speed must be adapted to the type of process and the alloy and its treatment state. Always observe the recommended rotational speed of our products.

With the rotational speed calculator, PFERD provides you with a free tool for determining drive operating speed, tool diameter and cutting speed.

What is the right contact pressure when using aluminium?

Despite the excellent thermal conductivity of aluminium, local overheating from excessive contact pressure can lead to local changes in microstructure when grinding. In the event of subsequent electrolytic surface treatment, this can have a negative effect on the metal’s decorative appearance.

Unlike conventional steel materials, lower contact pressure must be used when grinding aluminium alloys. That is the only way to prevent the high heating of the workpiece and achieve an excellent surface quality.

How do you protect workpieces and tools against overheating?

The use of grinding oils and lubricants prevents excessive temperature development and in the case of finer grains in particular, contributes to cooling.

How can corrosion be avoided on aluminium surfaces?

You should observe the following points without fail, in order to avoid contact corrosion of the fragments on the processing surface:

- The tools used (e.g., brushes) may not be made from copper alloys or steel.

- Do not use grinding or polishing discs that have already been used to process other metals. Strict tool separation is absolutely necessary!